The carrier is obliged to have fastening strips and to follow the general recommendations as regards security of loaded pallets.

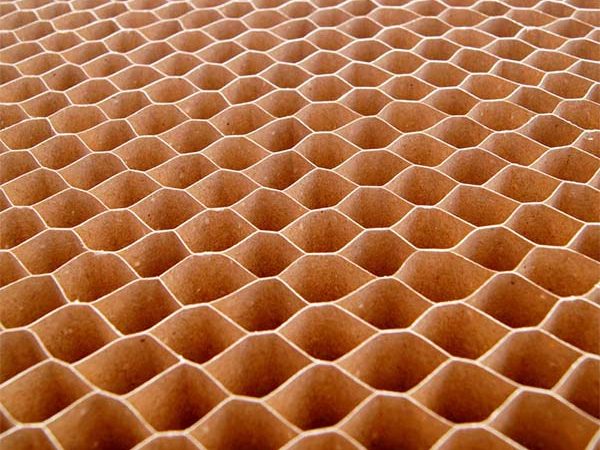

During storage of LDR-Ego honeycomb boards, make sure that the material is duly protected against weather. In a perfect situation, the boards are stored in heated, dry and draught-free rooms where relative humidity is from 40 to 75% and air temperature from 15 to 18 °C.

Before working, the material should be placed in an intermediate storehouse for the moisture content to get closer to the value expected during working. Storage in open storages or under station roofs is not recommended!

Honeycomb boards are to be stored horizontally on even and dry ground, in a closed building, under normal climatic conditions. The intermediate storehouses should have the same height and be placed at intervals from 0.8 to 1.1 m, depending on board thickness. If needed, proper edging protection must be provided. Storage and transport are to be performed according to the recommendations, forming stacks and following regulations on transport, storehouse and safety.

Less